Taian Haishu Machinery Co.,Ltd.

Telephone: +86-538-8606169

Fax: +86-538-8606169

Address: Zhouwangzhuang Village, Shankou Town

Taian City Shandong Province China

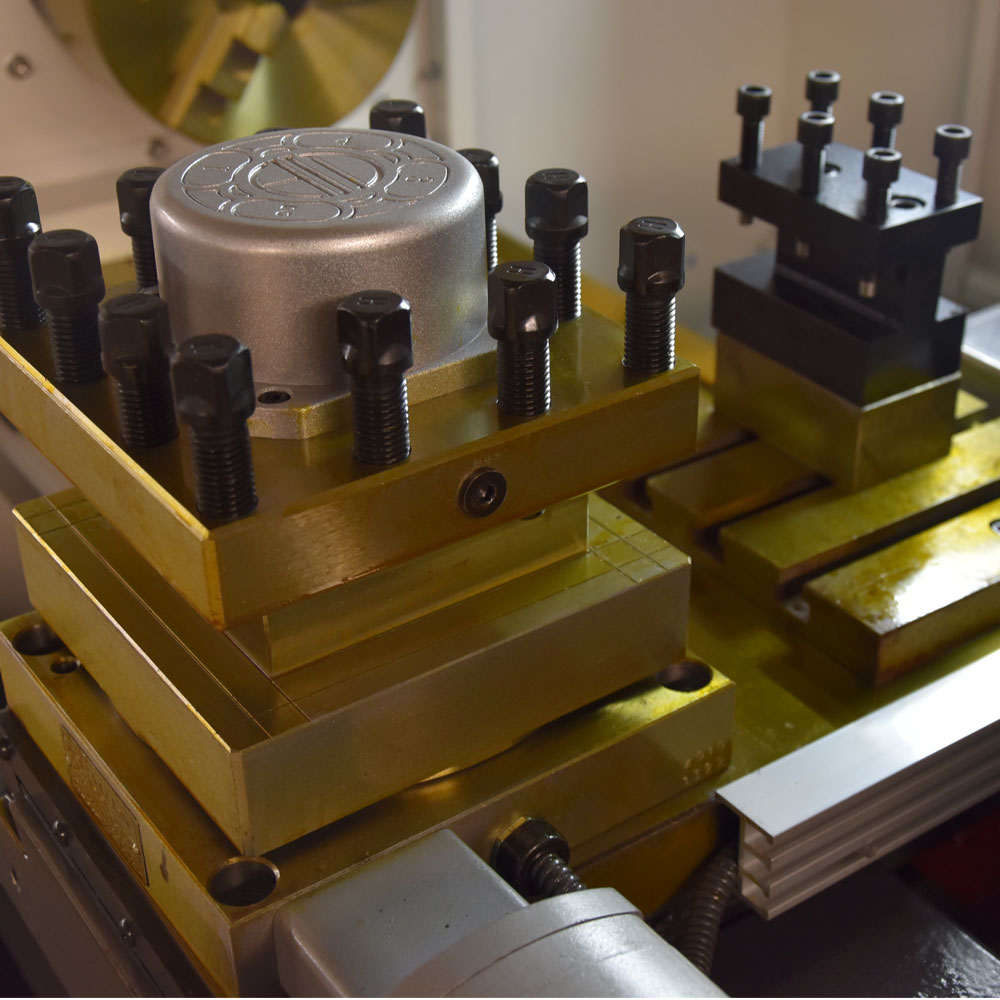

Discussion on Three Control Methods of CNC Lathe Manufacturers

Open loop control: refers to the control method without position feedback device. The machining accuracy is generally around 0.02-0.05mm.

Semi closed-loop control: refers to the installation of an angular displacement detection device on the open loop control servo motor shaft, which indirectly detects the displacement of the moving parts by detecting the angle of the servo motor and feeds it back to the comparator of the numerical control device. It is compared with the input command and controls the moving parts with a difference. The machining accuracy is generally around 0.01-0.02mm, and the accuracy is closed

Loop control: It is a linear or rotary detection device that directly measures the displacement or angular displacement value at the corresponding position of the final moving component of a CNC machine tool. The directly measured displacement or angular displacement value is fed back to the comparator of the CNC device and compared with the input command displacement. The difference is used to control the moving component and make it move strictly according to the actual required displacement. The machining accuracy is generally around 0.002-0.01mm.

What are the operating methods for precision CNC lathe machining

Firstly, digitize the geometric information and process information on the part drawing processed by the precision CNC lathe, that is, the relative motion trajectory of the tool and workpiece, the transformation of spindle speed and feed speed during the precision CNC lathe machining process, the switch of coolant, and the transformation of the workpiece and tool, all of which are programmed into a machining program according to the specified code and format, and then input the program into the CNC system. The CNC system, according to the requirements of the program, first performs corresponding calculations and processing, and then issues control commands to coordinate the coordinate axes, spindles, and auxiliary actions, achieving the relative operation of the tool and the workpiece, and automatically completing the processing of the parts.

CNC lathe research and development, every problem we can not be ignored!

How to make my machine have a longer service life?

How to make the equipment have higher production efficiency?

How to ensure that the machine is simple to learn?

... ...

Learn CNC lathes

From the beginning our website!

Global Service Hotline:+86-0538-8606169